Therefore, they should be excellent in rust prevention as well as sea-water and water resistance.

KCC produces Heavy Duty Protective Coatings with outstanding product capabilities including marine coatings, offshore plant coatings and water-based container coatings.

Furthermore, its competitiveness is well recognized by world-renowned shipping companies.

Offshore Coatings

It is also called marine production facility for exploration / drilling / extraction / production of marine resources buried deep in the sea. Typical examples are deep drilling rigs (drillship) and floating production storage offloading (FPSO).

These installations must be painted with highly functional offshore plant coatings that are difficult to maintain and repair once installed.

Offshore Structures

-

Fixed Platform

Platforms built on concrete or steel legs anchored directly onto the sea bed.

-

Jack-Up Rig

A type of mobile platform consisting of a buoyant hull fitted with a number of movable legs.

-

Semi Rig

Semi-submersible drilling rig.

-

Drill Ship

A maritime vessel often used for exploratory offshore drilling of new oil or gas wells in deep waters.

-

FPSO

Floating Production, Storage and Offloading (FPSO) unit is used to process hydrocarbons and store oil.

Track Records

-

Platform

22 projects

-

Jacket

7 projects

-

Drill Ship

6 projects

-

FPSO / FSO

7 projects

-

Drilling Rig

9 projects

-

Others

7 projects

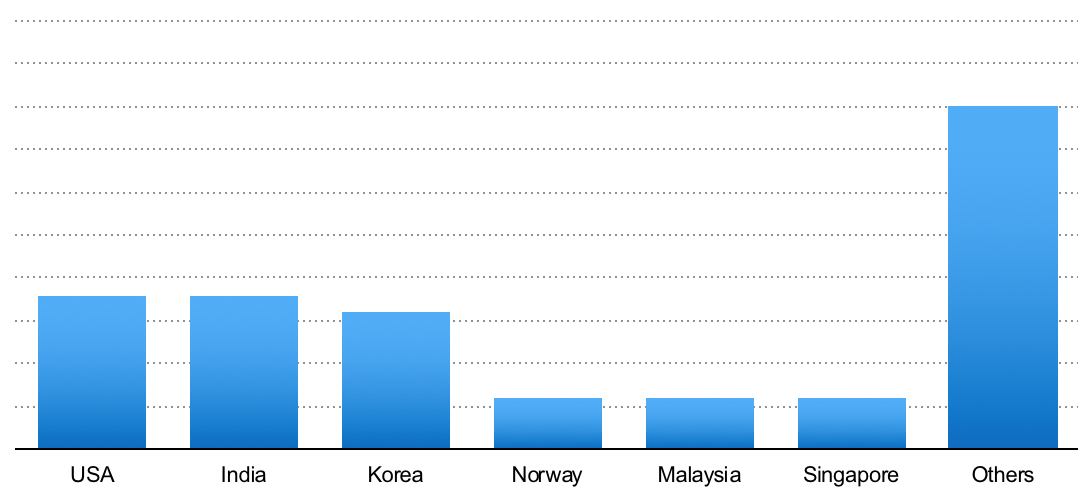

By Country

KCC Coating Systems for Offshore Steel Structures

| Areas | Coating Systems | |

|---|---|---|

| Atmospheric Zone | 1st | Inorganic Zinc (or Epoxy Zinc) |

| 2nd | Epoxy High-Build | |

| 3rd | Urethane (or Polysiloxane) | |

| Splash Zones | Glass Flake Reinforced Solvent-Free Epoxy | |

| Ultra High-Build Solvent-Free Epoxy | ||

| Unsaturated Polyester | ||

| Immersed Zones | Universal Epoxy | |

| Aluminium Pigmented Epoxy | ||

| Amide-Cured Epoxy | ||

| Fire Protective Zones | Passive Fire Protective Coatings | |

Ceritifcate [NORSOK M501 System]

| Standard | System No. | KCC’s approval system | Test Rev. |

|---|---|---|---|

| NORSOK M501 | System 1 | IZ180N (75u) + EP170QD (25u) + EH2350 (175u) + UT6581 (50u) | Rev.4 |

| EZ175 (75u) + EH2350 (110u) + EH2350 (110u) + UT6581 (50u) | Rev.4 | ||

| IZ180N (60u) + EP1700 (30u) + EH2030 (150u) + ST1020 (60u) | Rev.5 | ||

| EZ175 (75u) + EH2350 (175u) + UT6581 (60u) | Rev.5 | ||

| EH2350 (175u) + EH2350(175u) + ST1020(60) | Rev.5 | ||

| IZ180N (60u) + EP1700 (30u) + EH2351 (150u) + ST1020 (50u) | Rev.5 | ||

| EH2030 (175u) + EH2030 (175u) + ST1020 (60u) | Rev.6 | ||

| EZ175(60u) + EH2350(160u) + UT6581(60u) | Rev.6 | ||

| IZ182(S)(SB) (8u) + EZ175 (60u) + EH2352 (160u) + UT6581(60u) | Rev.6 | ||

| System 3B | IZ182 (15u) + EH2351 (175u) + EH2351 (175u) | Rev.4 | |

| EH2030 (160u) + EH2030 (160u) | K-4049 | ||

| EH2350 (160u) + EH2350 (160u) | K-4050 | ||

| EH2350(P) (160u) + EH2350(P) (160u) | K-4051 | ||

| EH2351 (160u) + EH2351 (160u) | K-4052 | ||

| EH2352 (160u) + EH2352 (160u) | K-4053 | ||

| System 4 | IZ180N (60u) + EP1700 (30u) + EH3200(GF) (500u) | Rev.5 | |

| EH2350(150u) + EH3200(N)(1,000u) | Rev.6 | ||

| System 5A | EZ175 (60) + EP1700 (50u) + FIREMASK 3200 (6000u) | Rev.6 | |

| System 7A | EH3200(GF) (1000u) + EH3200(GF) (1000u) | Rev.4 | |

| EH3200(GF) (300u) + EH3200(GF) (300u) | Rev.5 | ||

| EH2030 (175u) + EH2030 (175u) | Rev.5 | ||

| EH2351 (175u) + EH2351 (175u) | Rev.5 | ||

| PC4288 (600u) + PC4288 (600u) | Rev.6 | ||

| System 7B | EH2351 (175u) + EH2351 (175u) | Rev.4 | |

| EH2350 (175u) + EH2350 (175u) | Rev.4 | ||

| IZ182 (20u) + EH2350 (175u) + EH2350 (175u) | Rev.4 | ||

| IZ182 (15u) + EH2370 (175u) + EH2370 (175u) | Rev.4 | ||

| EH2030 (175u) + EH2030 (175u) | Rev.5 | ||

| IZ182(J) (15u) + EH2030 (175u) + EH2030 (175u) | Rev.6 | ||

| EH2350 (175u) + EH2350 (175u) | Rev.6 | ||

| IZ182(J)(S/B) (15u) + EH2350 (175u) + EH2350 (175u) | Rev.6 |

Certificate [ACQPA System]

| Standard | System No. | KCC’s approval system | Test Rev. |

|---|---|---|---|

| ACQPA | Im2 ANI | EZ175 (50u) + EH2351 (200u) + EH2351 (200u) | - |

| EP170QD (50u) + EH3200GF (400u) | - | ||

| EH2351(GF) (300u) + EH2351(GF) (300u) | - | ||

| EH2350 (225u) + EH2350 (225u) | - | ||

| EH2030 (225u) + EH2030 (225u) | - | ||

| EH3000 (225u) + EH3000 (225u) | - | ||

| Im2 ZNI | EP1700 (50u) + EH2030 (175u) + EH2030 (175u) | - | |

| C5Ma | IZ180N (75u) + EP1700 (30u) + EH2350 (175u) + UT6581 (50u) | - | |

| EZ175(75u) + EH2350 (200u) + UT6581 (50u) | - | ||

| IZ180N (75u) + EH2030 (200u) + UT6581 (50u) | - | ||

| IZ180N (75u) + EP1700 (30u) + EH2030 (175u) + ST1020 (50u) | - | ||

| C5Mm | EZ175 (75u) + EH2350(GF)(200u) + EH2350(GF)(200u) | - | |

| IZ180N (75u) + EP1700 (30u) + EH3250 (GF) (375u) | - |