Heavy Duty Coatings

The Heavy Duty Protective Coatings help to extends the lifespan of large steel structures exposed to highly corrosive environment for a long time such as ships sailing across the oceans and marine plants standing in the middle of the sea and makes the exterior look more beautiful.

Therefore, they should be excellent in rust prevention as well as sea-water and water resistance.

KCC produces Heavy Duty Protective Coatings with outstanding product capabilities including marine coatings, offshore plant coatings and water-based container coatings.

Furthermore, its competitiveness is well recognized by world-renowned shipping companies.

Therefore, they should be excellent in rust prevention as well as sea-water and water resistance.

KCC produces Heavy Duty Protective Coatings with outstanding product capabilities including marine coatings, offshore plant coatings and water-based container coatings.

Furthermore, its competitiveness is well recognized by world-renowned shipping companies.

Marine Coatings

As a global leader in the marine paint industry in the 21st century, KCC has been recognized for its superior performance both domestically and globally. With our ceaseless efforts in technological innovation, we invest more than 5% of our annual revenue in research as the development expenses for our customers' satisfaction. As a result of these efforts, KCC has successfully completed more than 3,800 new-building projects and more than 5,500 dry-docking projects by developing and supplying superior quality products and providing complete on-site construction supervision. (As of the first half of 2017)

1. Characteristic Features

- Outstanding anti-abrasion and anti-shock properties and excellent resistance to sea water, crude oil and fuel oil, etc.

- Environmentally friendly (High SVR, Low VOC)

- Easy application and applicable even in low temperatures (down to -18℃/-0.4F)

- Excellent anti-corrosive properties (Approval IMO PSPC TAC by class, Pre-qualified by NORSOK M501, ACQPA)

2. Product Information

- Korepox EH2350

- Korepox EH2351

- Korepox EH2352

- Korepox EH2030

| Product | Type | SVR (%) | TSR (㎡/L, in 125㎛) |

Typical D.F.T (㎛) | Recoating interval (Min./Max.) | Immersion time (20 ℃) |

|---|---|---|---|---|---|---|

| Korepox EH2350 | Epoxy anti-abrasion | 80 | 6.40 | 100 ~200 | 3H /15D | 2D |

| Korepox EH2351 | Epoxy anti-abrasion | 72 | 5.71 | 100~200 | 3H /15D | 3D |

| Korepox EH2352 | Epoxy anti-abrasion with aluminum pigments |

70 | 5.60 | 100~200 | 3H /30D | 3D |

| Korepox EH2030 | Epoxy anti-abrasion with aluminum pigments |

70 | 5.60 | 100~200 | 3H /15D | 3D |

[Notes] Recoating interval with itself, Immersion time : Body, H : Hours, D : Days

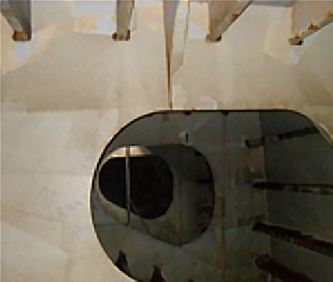

3. Reference

After 180 months

- Owner : Flopec / Ecuador

- Ship's name : M/T Cotopaxi

- Type : 65K DWT COT

- Date of Delivery : February 1999

- Applied system : Korepox EH2350 125㎛x 2 / Total 250㎛

- Date of Survey : February 2014 (180 months)

After 151 months

- Owner : Sea Justice SA / Greece

- Ship's name : M/V Endless

- Type : 73K DWT B/C

- Date of Delivery : January 1999

- Applied system : Korepox EH2350 125㎛x 2 / Total 250㎛

- Date of Survey : August 2011 (151 months)

After 148 months

- Owner : Flopec / Eduador

- Ship's name : M/T Cotopaxy

- Type : 65K DWT COT

- Date of Delivery : February 1999

- Applied system : Korepox EH2350 125㎛x 2 / Total 250㎛

- Date of Survey : June 2011 (148 months)