NEWS

|

Environment-friendly Marine coatings going strong 2017-11-09 |

|---|

|

The shipbuilding industry, which is the main industry of marine coatings, is recently experiencing diverse changes due to a sharp decline in ship operations, and strengthened environment-friendly regulations of international ship related organizations. The International Maritime Organization (IMO) in particular introduced the *Energy Efficiency Design Index (EEDI) for all new ships that have a contract from 2013, and a type of carbon emissions trading system and carbon tax according to the *Energy Efficiency Operational Indicator (EEOI). This has created a turning point that has started a competition for fuel efficiency among shipyards. EEDI is now one of the most important elements that evaluate shipyard competitiveness. It is a regulation that limits the carbon emission volume of a ship, and if the standard is not met, a ship cannot be delivered. This indicates that the ship building industry is changing into an industry based on a competition of technology, in addition to cost.

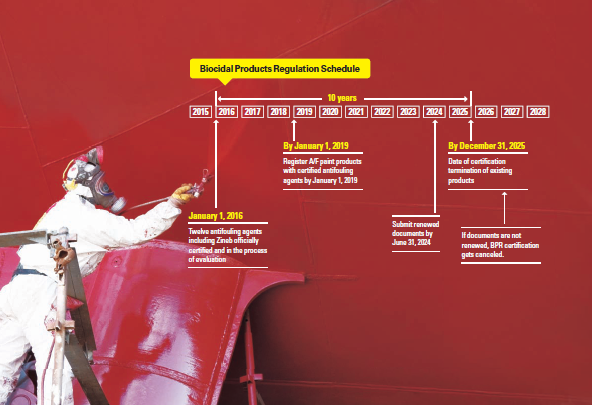

Antifouling agents and paint products need to go through the processes regulated to acquire certification, and ships that use A/F paint with antifouling agents that are not certified may not even be allowed to enter any ports in EU countries. The whole world is making continuous efforts as such to protect the environment, and related regulations will be reinforced further in the future. Furthermore, a new law was enacted in Korea this year according to the Air Environment Preservation Act to reduce the amount of *Volatile Organic Compounds (VOCs) in paint. The goal of the law was to reduce VOCs to improve air quality and the quality of life of people. |