R&D

We promise a brighter tomorrow via the technological innovation. We are capable of showcasing high-quality and high-functional products with creative designs as we have concentrated our efforts on R&D activities while actively applying the customers’ needs and changing market trends.

The KCC’s Central Research Institute

As a general chemical research institute, the Central Research Institute (CRI) has examined the entire precision chemical engineering fields from inorganic and organic materials to composite materials. The CRI has strengthened the foundation to make the next-generational growth by investigating precision chemistry of advanced materials including building materials, organic materials for the electric/electronic/semiconductor industry, and silicone. We have also spared no efforts in developing future technologies including nano materials, ceramic composite materials, and alternative energy by securing skillful research talents with the bold investment.

We added the Construction Material Research Laboratory and Structural Test Laboratory in 2010 to study the next-generation’s green future homes. We completed the construction of the Next-generational R&D Building in the area over 23,150 ㎡. By doing so, the CRI fulfills the social responsibility by making innovation with the sustainable technology. We will continue to focus on securing the global technological competitiveness in the research buildings (established in over 132,322 ㎡) in the land of 264,463 ㎡.

Major R&D activities

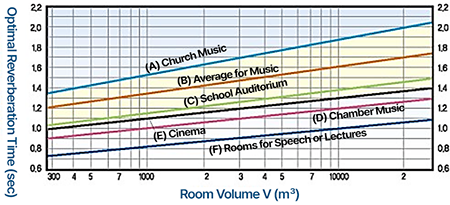

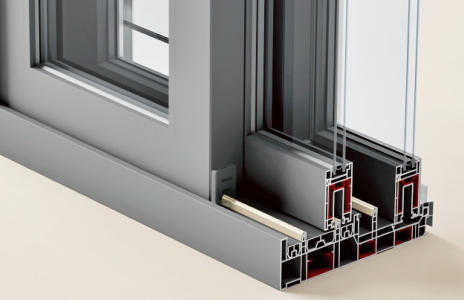

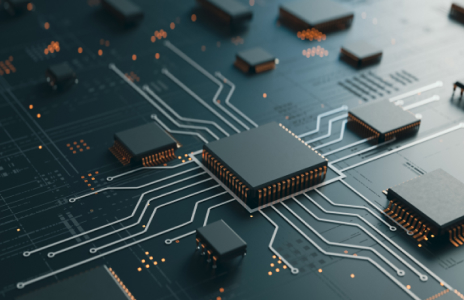

In terms of the organic material study, we examine water and solventless coatings, free of volatile organic compounds (VOCs) but maintaining the properties of the existing soluble coatings, to respond to the regulations on harmful chemicals. As for the inorganic study, we investigate high-efficiency building materials and system windows including high-insulating windows and heat-insulating materials to build the “zero energy house.” We also study parts for the electric/electronic use, electronic materials, and adhesives, which are applicable to the new business areas including semiconductor memory, mobile, and power modules for hydrogen and electric cars.

-

Study on organic materials

Study on organic materials

- Study green coating products including water-soluble and high solid materials.

- Examine green, high-functional synthetic resin.

- Investigate the application of coatings to automotive, ships, general industry, architecture, anticorrosion, and the PCM.

-

Study on inorganic materials

Study on inorganic materials

- Study eco-friendly, high-functional inorganic products.

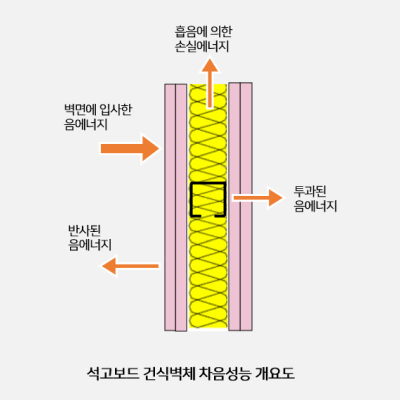

- Investigate the building material system.

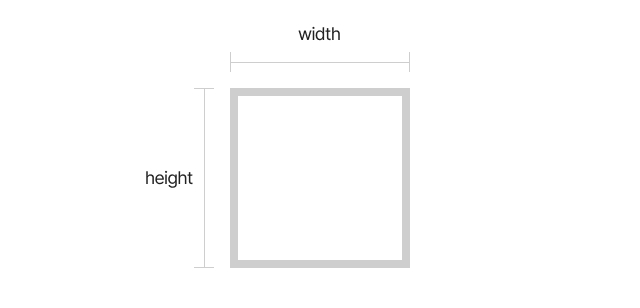

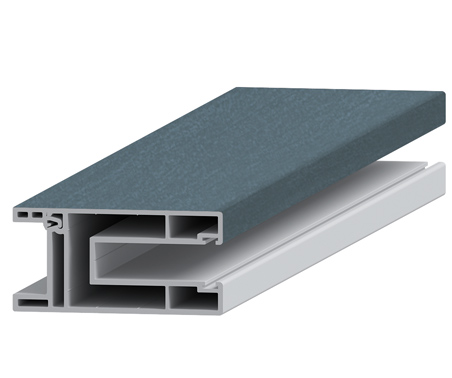

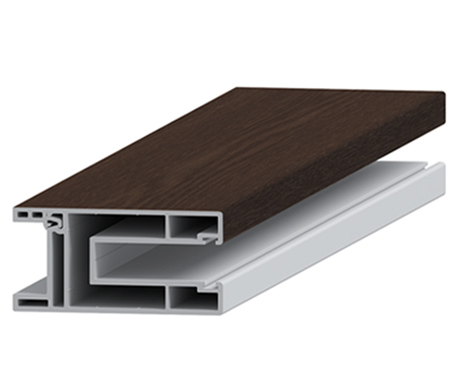

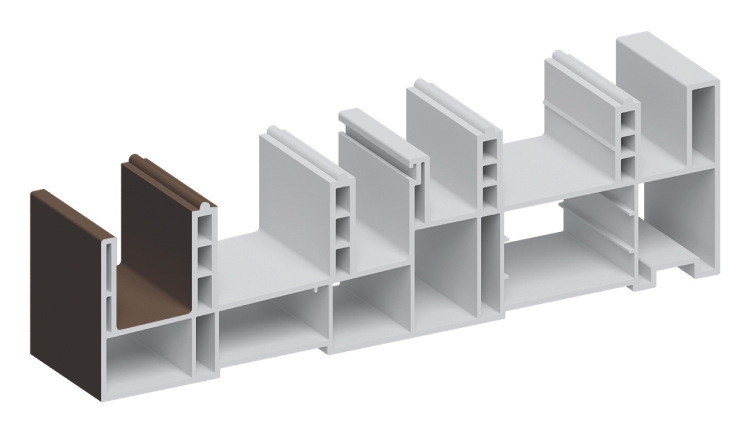

- Examine high-insulating, high-efficiency window systems.

-

Study on other materials

Study on other materials

- Examine electronic materials for the hydrogen and electric car operation.

- Study electronic materials for the semiconductor and display.

- Investigate ceramic materials for the electronic industry.

-

Awarded the Minister’s Awards of the Ministry of Trade, Industry and Energy at the ‘Corporate Intellectual Property Awards 2024’

Recognized as a company contributing to national industrial development by strengthening corporate intellectual property capabilities and spreading intellectual property know-how

Korea Intellectual Property Association

-

KS-QEI(Korean Standard Quality Excellence Index)

Won the best prize in 4 areas including water & oil paint, the gypsum tex, glass wool, and windows for 9 consecutive years, 7 consecutive years, 5 consecutive years, and 3 consecutive years, respectively.

Korean Standards Association (KSA) -

KS-WEI(Korean Standards Well-Being & Environment Index)

Ranked no. 1 in the windows and eco-friendly (water-soluble) paints for construction for 4 consecutive years and 2 consecutive years, respectively.

KSA -

Recognized in the National Quality Management Convention

Won the President’s citation in the CEO and executives area.

Ministry of the Interior and Safety (MOIS) -

Bronze prize in the National Convention on Quality Control Circle

Gimcheon, Munmak and Jeonju Plant 2 won a bronze prize.

The Ministry of Trade, Industry and Energy (MOTIE)

-

The National Convention on Quality Control Circle

With the intelligent TPM activity, the circle activity increased the overall efficiency of the facility by using powder coating, “karumel.” (Reduced the stop time by improving a powder-lined steel pipe.)

The Ministry of Trade, Industry and Energy (MOTIE) -

Quality certificates on building materials and others

The KCC’s FIREMASK AQ-1000 and AQ-2000 obtained Korea’s first certifications on water-soluble fireproof coatings for the steel-frame fireproof construction.

The Korea Institute of Civil Engineering and Building Technology (KICT)

-

A prize in Excellent KS

Selected as an excellent firm recognized by KS.

Korean Agency for Technology and Standards (KATS) / KSA -

Excellent Member Company Award

Selected as an excellent member company of the KSA.

KSA -

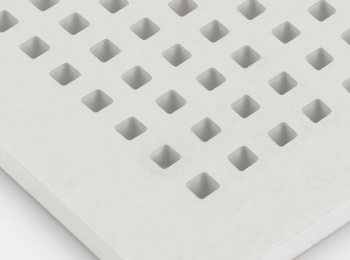

The World-class Product of Korea

The two types(Search A/F795 and Korepox EH 2350) of coatings for ships and vacuum insulation materials for the electric/electronic use (ceramic for VI)

The MOTIE -

The Korea Laboratory Accreditation Scheme(KOLAS)

Fire and fireproof areas

The Korean Agency for Technology and Standards (KATS) of the MOTIE

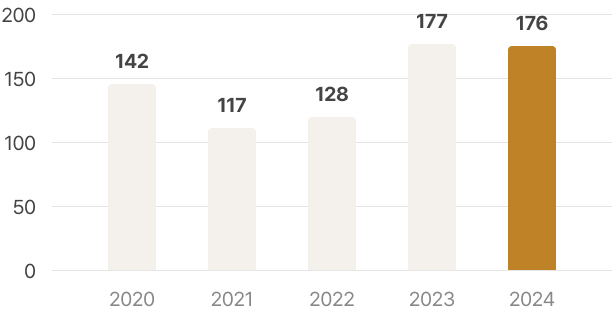

[㎡]

[㎡]