Insulation

KCC thermal insulation is an inorganic material that does not burn and improves energy efficiency and safety.

Delicate and flexible artificial mineral fibers have excellent insulation and sound absorption performance It helps minimize fire damage by increasing the golden time in case of a fire.

KCC Cerak Wool

KCC Creak wool is an ultra-high temperature fire-resistant insulation material that maintains stable and excellent quality even at ultra-high temperatures above 1,000℃.

It is a high-temperature fireproof insulation material manufactured by the spinning method.

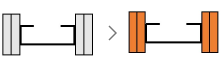

KCC, which developed ceramic fiber for the first time in Korea, has developed and produced Spun Fiber, which is superior in quality to Blown Fiber by the existing Blowing method.

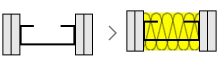

Spun Fiber has a longer fiber length than Blown Fiber, so it has excellent tensile strength and overall physical properties.

Features & advantages

Click the icons.

-

As an inorganic material that is chemically stable and highly resistant to acids, alkalis, and other chemicals, it does not decay or deteriorate, making it suitable for semi-permanent use.

-

It is an excellent ultra-high temperature, fireproof thermal insulation material with outstanding bio-solubility as it is quickly dissolved and emitted in the body even when it is inhaled. (Features of bio products)

-

It is an excellent ultra-high temperature, fireproof thermal insulation material with outstanding eco-friendly bio-solubility as it is quickly dissolved and emitted in the body even when it is inhaled. (Features of bio products)

-

Low-heat conductivity at high temperatures provides excellent thermal insulation.

-

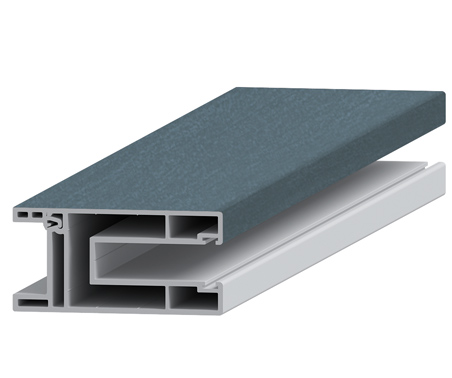

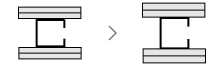

It is lighter and more flexible than the existing fireproof structures, so it is easy to install in any areas.

-

Product stability is excellent at high temperatures.

-

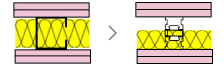

With excellent heat insulation, it can save fuel costs and make think, so the effective area gets wider with easy installation. Thus, it leads to a reduction in installation time caused by labor cost saving and easy maintenance.

[㎡]

[㎡]