Advanced Materials

KCC's Advanced Materials are the solutions for the future.

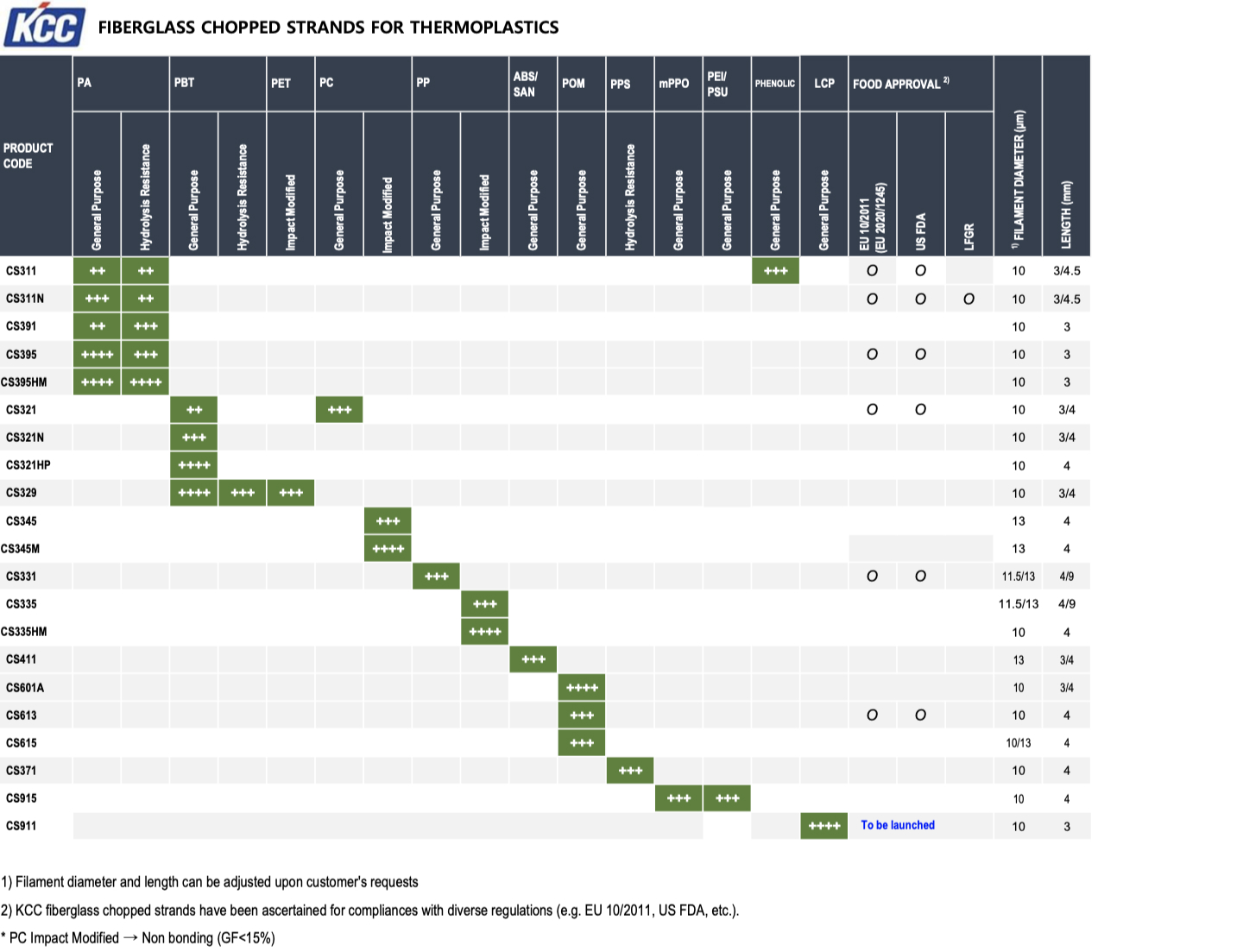

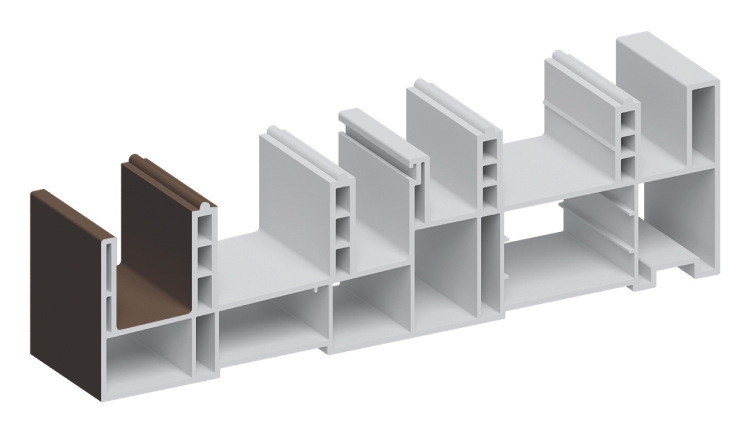

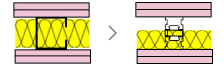

Glass fiber is a composite material with a thickness of ㎛ where the filaments created from the glass melted with inorganic materials including agalmatolite and limestone at extremely high temperatures of over 1500℃ are surface treated.

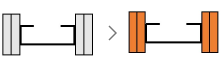

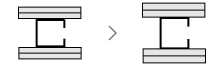

- Commodity plastics

- Brittle, red-short

low dimensional stability

- Glass fiber

- The KCC’s composite materials

- Reinforced plastics

- High physical strength

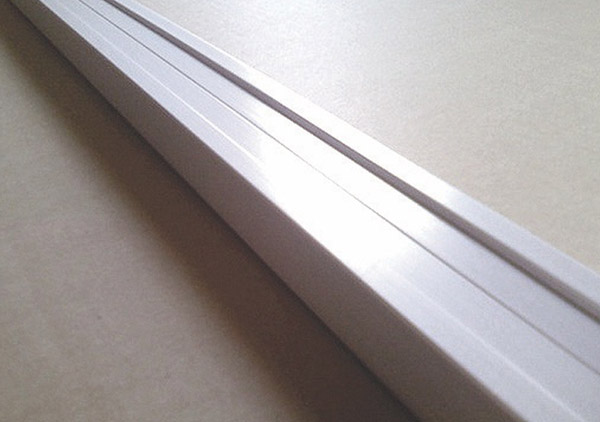

The glass fiber produced by the KCC includes the Chopped Strand, Chopped Strand Mat, Direct Roving, Conventional Roving, Woven Roving, and Tissue. It is widely used across the electric·electronic, automotive, and civil engineering industries.

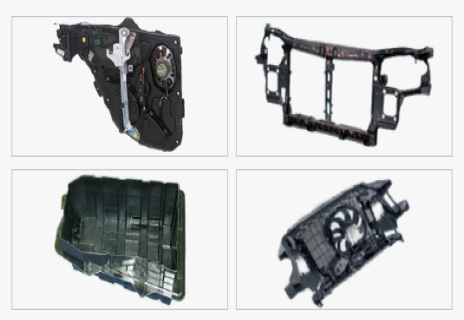

Glass fiber for automotive parts

The development of green car manufacturing technology rises due to the enhanced global environmental regulations and increasing oil prices. The engineering plastics used to reinforce automotive interior/exterior materials can provide various physical properties including being lightweight (by replacing the existing metal materials), dimensional stability, heat insulation the heat resistance (required to an engine), corrosion resistance, chemical resistance, and hydrolysis resistance.

Application

- Electric vehicle components : Connectors, actuators

- Interior materials : Seat support, ceiling stiffeners, major parts surrounding a driver’s seat, gears

- Exterior materials : Car body, reinforced structures, various automotive modules (front, rear, door module), under cover guard, etc.

- Engine/fuel parts : Radiators, intake manifold

- Railway vehicle flooring, bus body, freight containers, trucks, spoiler

Application example

[㎡]

[㎡]