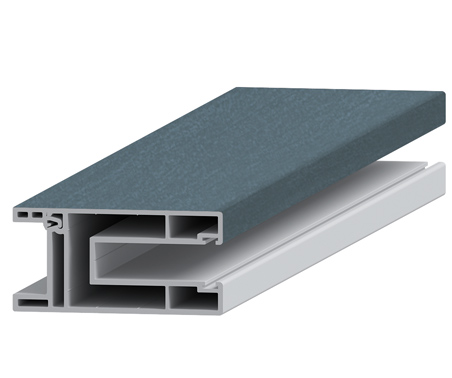

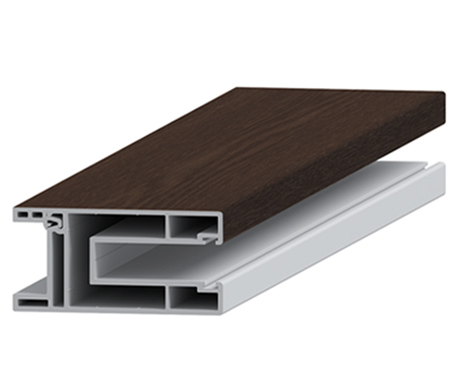

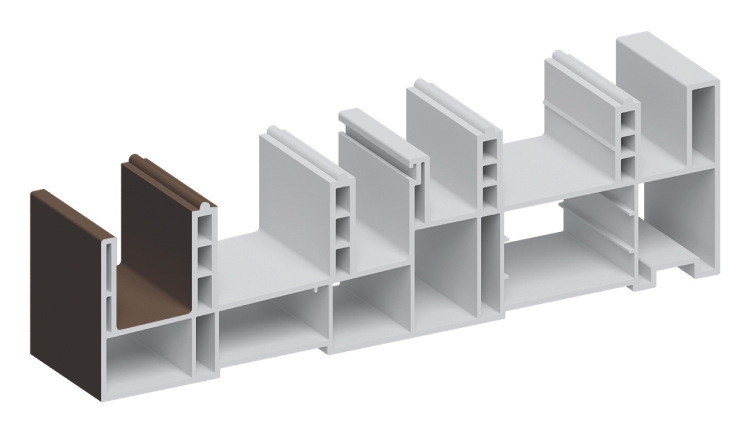

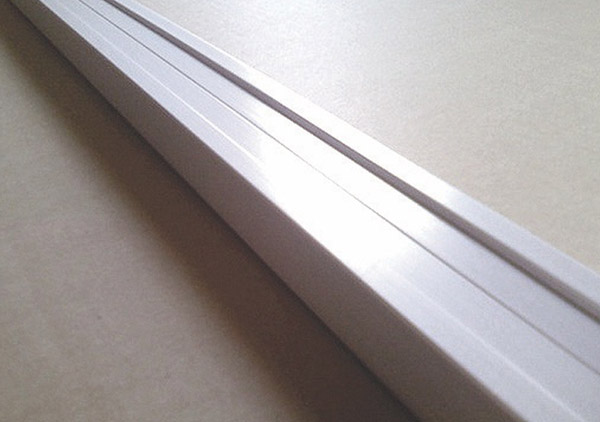

Coatings

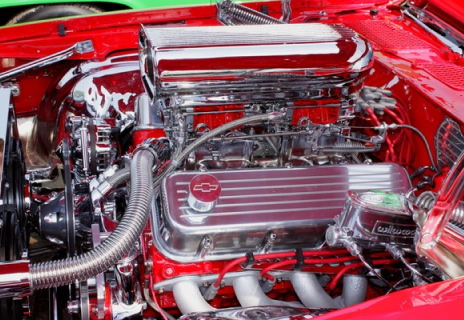

Powder Coatings Eco-friendly with a Variety of Patterns

It is free of volatile substances since any volatile solvents or diluents like water are not included. Accordingly, there is no risk of being addicted to solvents and has a low risk of fire. Pollutant issues such as air and water pollution can be minimized.

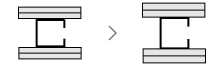

Once the film is fabricated, it does not crease or drip. The applicability is excellent as the viscosity adjustment does not need to be adjusted.

Powder coatings are applied like spraying the powder, instantly forming a film when it is adhered to the sprayed surface, which forms a thick application without no additional coatings. Any remaining powder not attached to the surface can be collected for reuse. Thus, the economic feasibility is also very high.

-

High Stability

Free of volatile substances including volatile solvents or diluents

-

Excellent Applicability and Economic Feasibility

No need to adjust viscosity and can be reusable after the collection.

-

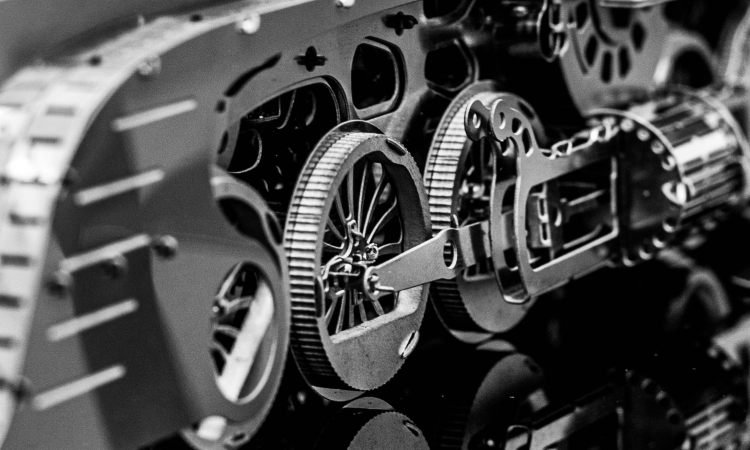

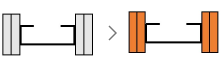

Anti-corrosive and High Insulation

Special functions including corrosion prevention and insulation.

-

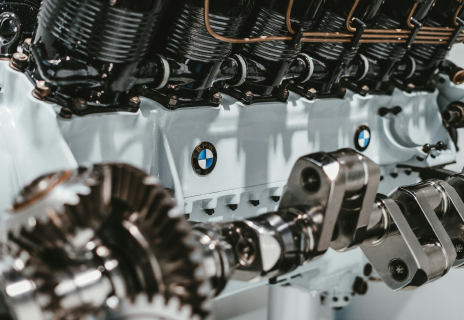

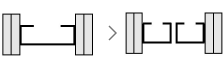

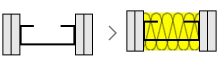

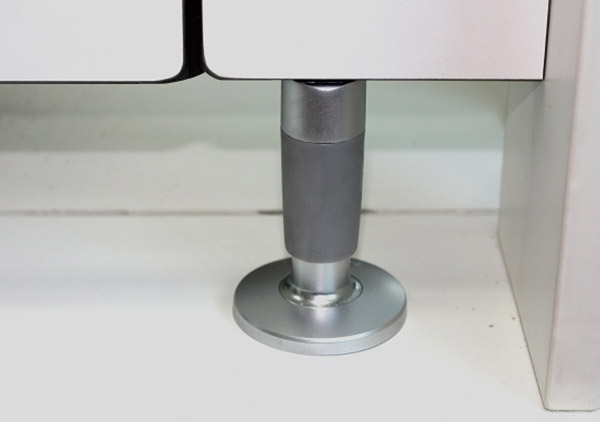

Steel Pipe Protection

Protect various steel pipes and increase transportation efficiency.

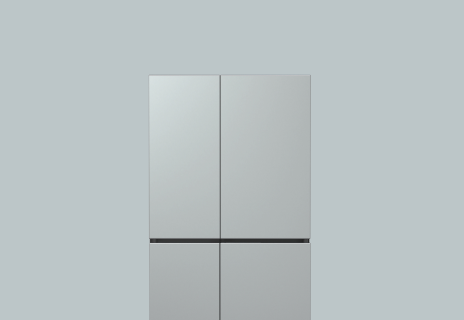

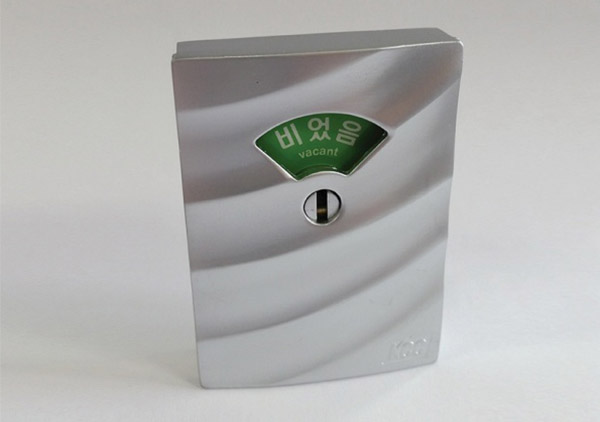

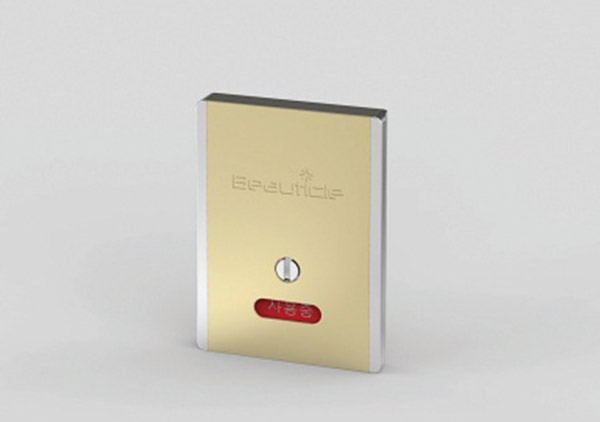

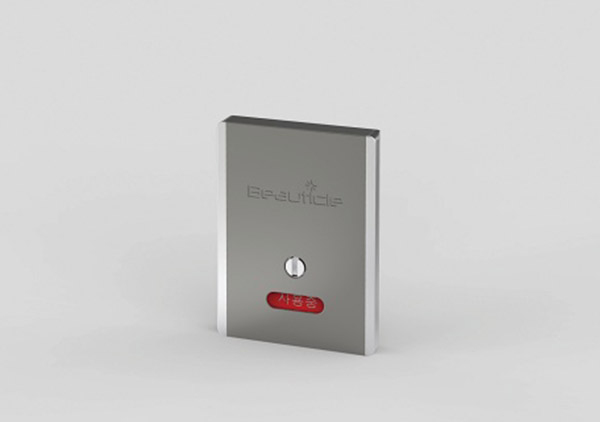

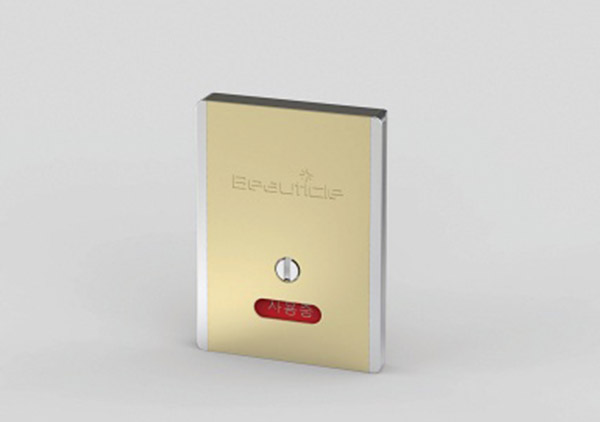

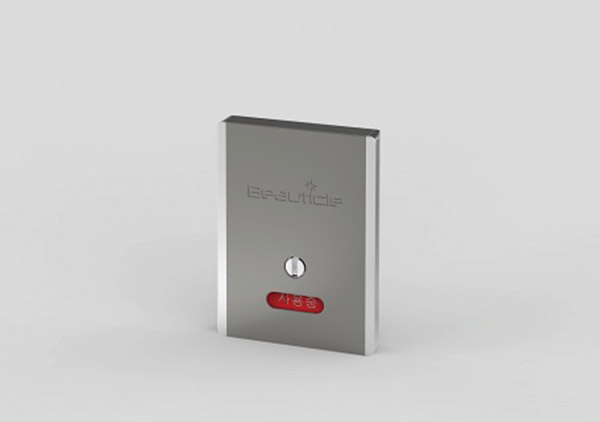

Powder Coatings for Electronics · Home Appliances

By reflecting the consumers’ needs regularly, we produce high functional products such as the 2 coating system, self-cleaning, high levelling, negative ions and antibacterial powder coatings, whose corrosion resistance is improved in a highly corrosive environment.

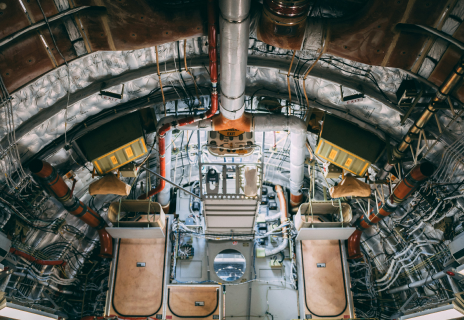

Moreover, by obtaining international certificates such as KS and UL, we have made the efforts to expand the applications under severe environmental conditions including ships, nuclear power plants and overseas plants.

[㎡]

[㎡]