Coatings

Marine Coatings Protecting ships from harsh marine environments

As the coatings for ships and marine plants, it aims at protecting structures in extreme environments.

Ships must secure stability with an excellent anti-corrosive performance compared to the ground structures and be easy to maintain.

During the operation, ships are exposed to droplets and strong UV rays, so anti-corrosive and antifouling coating systems are required.

-

Protect Hull Surface

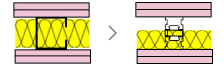

Contain sea creatures attachment and rust generation.

-

Save Fuels

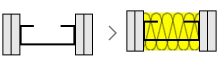

Increase fuel efficiency by reducing the friction resistance of ships.

-

Protect Environment

Helpful in reducing operation costs

and GHG emissions.

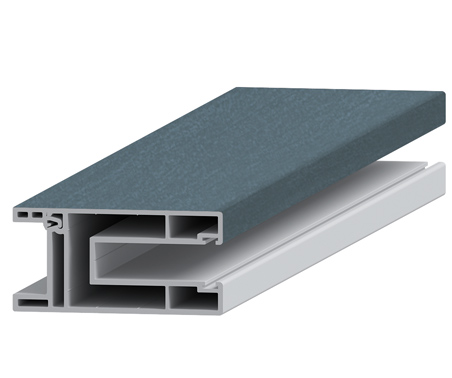

Vessels

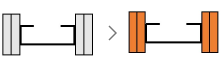

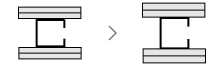

Vessels are classified by purposes including merchant vessels, special-purpose vessels, battleships, and fishing boats. Different marine coatings are recommended to each structure of the vessels. Vessels are largely comprised of the exterior (hull) and interior (cargo tank, residential area, engine room, etc.).

Vessels Application example

Offshore

Offshore is called the marine production facility since it explores/drills/excavates/produces deep underwater marine resources.

Representative facilities include a drillship drilling deep sea crude gas and FPSO (Floating Production Storage Offloading).

Recommended coatings and specifications differ to each facility since each facility has different designs and unique parts.

Offshore Application example

Semi-rig (semi-submersible drilling rigs, semi-submersible drilling rig), drill ship, jack-up rig, etc.

Stationary equipment (platform), floating equipment (FPU, FPSO, LNG-FPSO), etc.

[㎡]

[㎡]