Interior / Exterior

KCC interior and exterior materials are developed and produced with the quality of housing and disasters in mind.

We produce a variety of functional gypsum boards, from Regular Gypsum Board to Fireproof, Waterproof, Fire&Waterproof, Anti-bacterial, Soundproof, and High Waterproof Gypsum Board, and Ceiling Boards of beautiful patterns and stable colors to meet customer needs.

KCC Gypsum Board

-

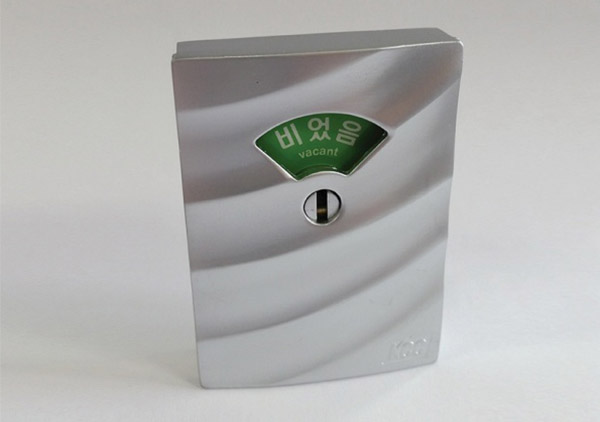

What is the HB Mark?

A collective quality certification system of granting an eco-friendly certification grade based on the strict and thorough quality certification tests performed by a qualified testing agency. The tests include the degree of organic compounds(HCHO, TVOC) emissions on the construction materials produced domestically and overseas. (Related to Article 11 of the INDOOR AIR QUALITY CONTROL)

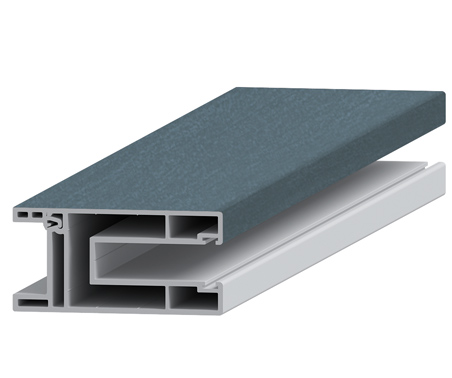

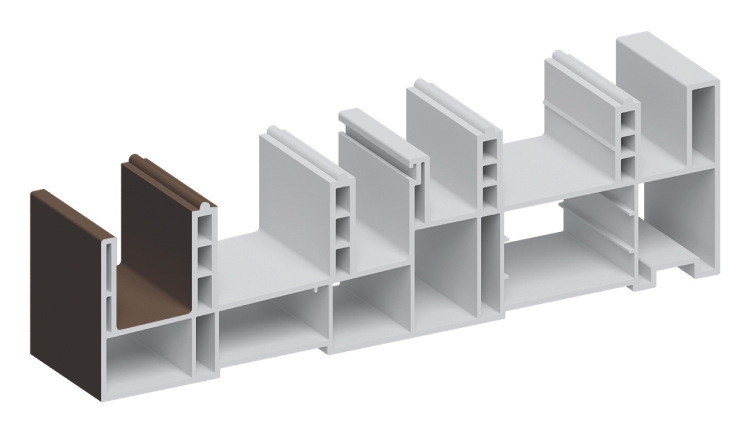

The KCC gypsum board is made by mixing by-product gypsum and FGD(Flue Gas Desulfurization) gypsum with water and then forming this mixture into board shapes using paper coating. It comprises of a crystallized gypsum core covered in two layers of paper and satisfies the key interior performance requirements of incombustibility, insulation, and soundproofing. In addition, various dry processing methods are applied to lower installation costs and KCC-exclusive CD(Controlled Density) technology makes our board perfectly suited for application in the modulation and weight-saving trends of today's modern buildings, and also has high economic efficiency.

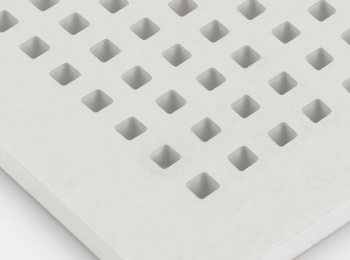

KCC gypsum board boasts a variety of popular GB-R (Regular Gypsum Board), Perforated Sound Absorption Board used for areas in need of sound absorption, Waterproof Gypsum Board that is used for humid places including bathrooms and kitchens, Fireproof Gypsum Board for fire-resistant and soundproof structures, Antibacterial Gypsum Board that deters propagation and proliferation of mildew, High Waterproof Gypsum Board with high waterproof and mold-resistance capabilities, multifunctional Fireproof & Waterproof Gypsum Boards, Soundproof Gypsum Board, and High-Impact Gypsum Board, and High Impact & Waterproof Gypsum Board. We will sustain to develop and produce new and multi-functional gypsum boards necessary to our customers.

Features & advantages

Click the icons.

-

This product received the highest grade in Healthy Building regulations qualified by the Korea Air Cleaning Association(KACA) according to released intensity of Building materials manufactured in Domestic and Foreign industries.

-

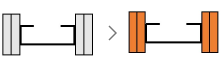

Controlled gypsum core density resulted in the drastic weight reduction for easier board transportation and handling and greater board strength.

-

Light and easy to install, so it is an economical product that can show you structural cost savings in your buildings.

-

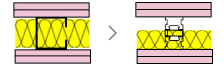

The waterproof gypsum board is adequate for bathrooms and kitchens since the special waterproof process on the core plaster helps it to keep high levels of strength and waterproof performance in a humid environment.

-

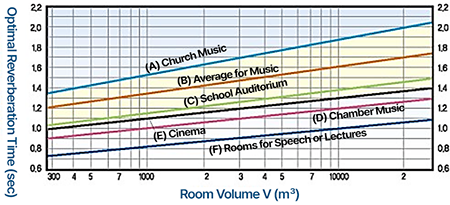

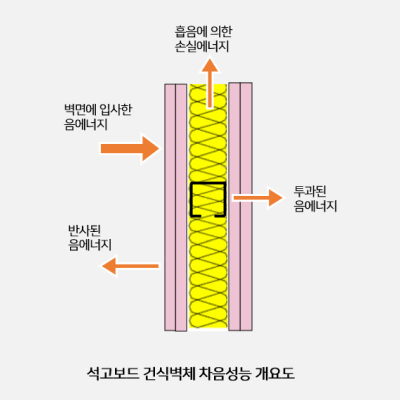

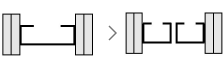

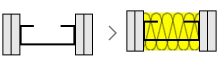

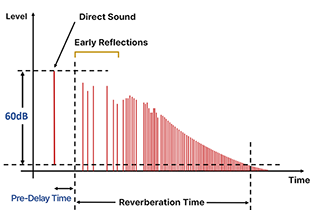

The board's combined use of gypsum and paper gives it unsurpassed soundproofing performance than other materials of equal or similar mass, blocking out many of the external noises and thereby providing a quiet indoor environment.

-

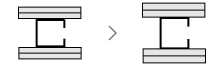

With relatively low thermal conductivity, it blocks out the summer heat and the winter cold, enhances thermal efficiency, facilitates indoor temperature control, and provides even greater insulation performance when used in conjunction with KCC Glass Wool, Mineral Wool and other insulation materials.

-

Gypsum content is crystal water that provides initial fireproof and combustion delay properties to the board. In particular, it has been enhanced with fire-resistance materials and inorganic fibers for superior fire-resistance performance and is therefore suitable for application as a fire-resistant or fireproof structure.

-

It can be cut with ease using only a knife, is easy to install on walls and ceilings, and can be applied with paint, wallpaper, and various other types of finishes.

-

There's virtually no contraction or expansion brought on by changes in temperature or humidity levels, which means you won't have to worry about post-installation twisting or lightweight expansion with the joints.

-

It features a gypsum core that has undergone antibacterial treatment, which gives it the ability to suppress the spreading and multiplication of mildew during the installation process (1 month). Test strain

- Aspergilus brasilensis ATCC 9642

- Talaromyces pinophilus ATCC 11797

- Chaetomium globosum ATCC 6205

- Trichoderma virens ATCC 9645

- Aureobasidium pullulans ATCC 15233

[㎡]

[㎡]