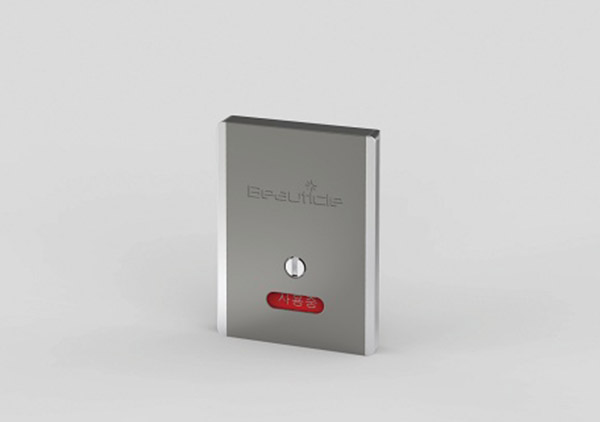

Coatings

Automotive (OEM) Coatings With Strong Durability and a Beautiful Look

It is designed for exceptional performance such as durability against UV rays, acid rain, salt, oil, and chemicals within the vehicle while offering finest appearance.

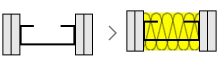

We offer improved performance along with higher quality by fully integrated coatings system through ED coat, primer, basecoat, and clearcoat.

-

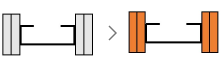

Korea’s 1st Water-Borne Basecoat

The first in Korea developed waterborne basecoat completed with our own technology

-

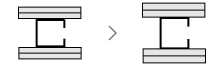

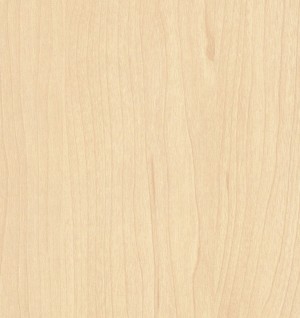

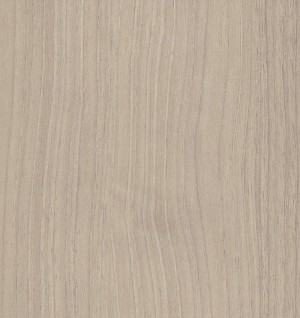

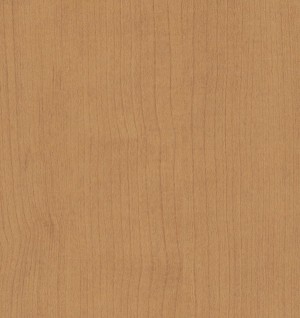

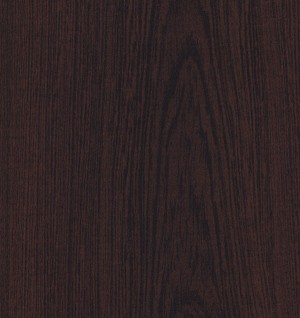

Exceptional appearance

Automatically develops color formula to each consumer with Color-Navi program

-

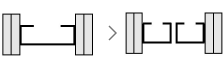

Excellent efficiency and productivity

Enhance the coating quality and gloss maintenance by improving scratch resistance.

EC (Electrodeposition Coatings)

Cationic ED coat is used as a primer for vehicle and it continue to bring ecofriendly, cost-saving solutions to the automotive industry. The latest trend in ED coat is optimizing Zirconium Pretreatment in response to the expansion of Electric vehicles. In addition, we are developing Low-Cure products to achieve Carbon Neutrality and maximize cost efficiency for our customers.

[㎡]

[㎡]